| หากต้องการใบเสนอราคา / ใบแจ้งหนี้ ติดต่อได้ทาง LINE Official: @mikroelec |

|

- จำนวนและราคาสินค้าที่มีอยู่จริงจะตรงกับในเว็บ

- ถ้ากดใส่ตระกร้าได้แสดงว่ามีสินค้าพร้อมส่ง หากจำนวนไม่พอจะมีข้อความแจ้งจำนวนคงเหลือให้ทราบ

- การรับ/ส่งสินค้ามี 3 รูปแบบคือ ส่งพัสดุ / มารับเองที่ร้าน / บริการแอปขนส่งเช่น Grab, LALAMOVE, ฺBolt, อื่นๆ

ร้านไมโครอิเล็กทรอนิกส์ จะหยุดทำการในวันที่ 25/10/2568 ถึง วันที่ 26/10/2568

หากสั่งซื้อสินค้าในวันดังกล่าว จะจัดส่งสินค้าให้ในวันที่ 27/10/2568ขออภัยในความไม่สะดวก.. |

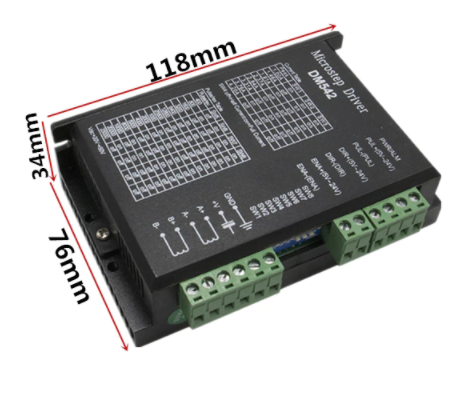

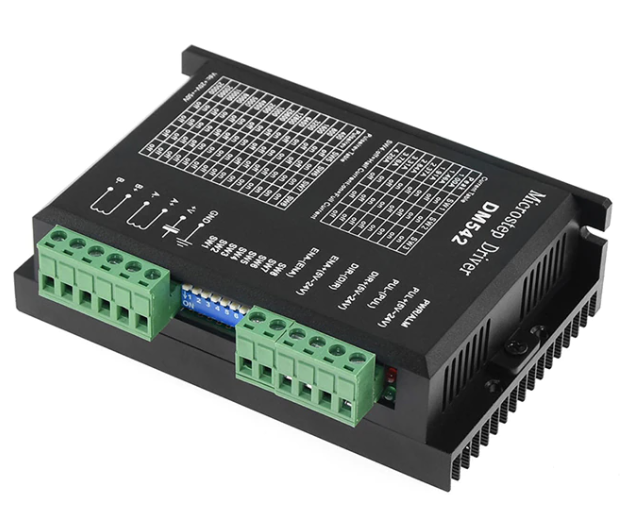

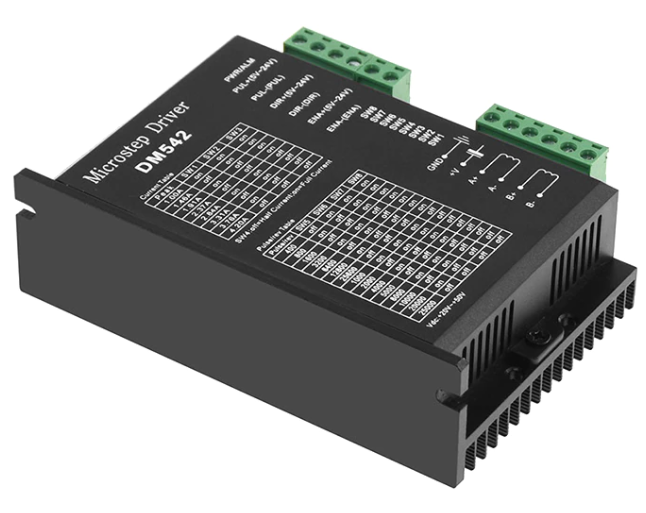

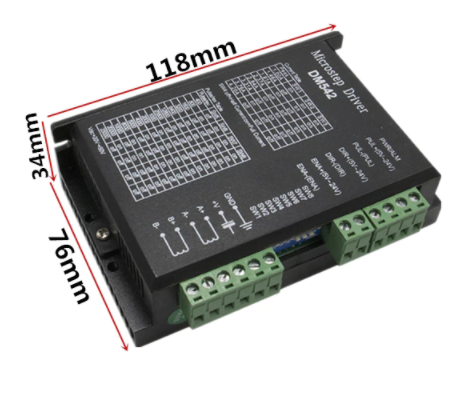

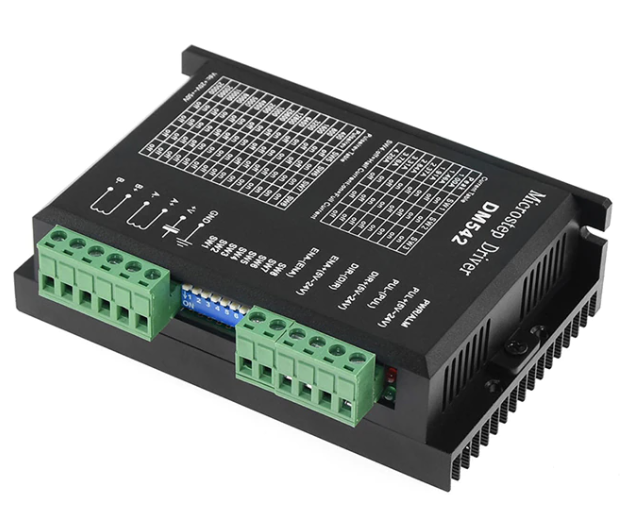

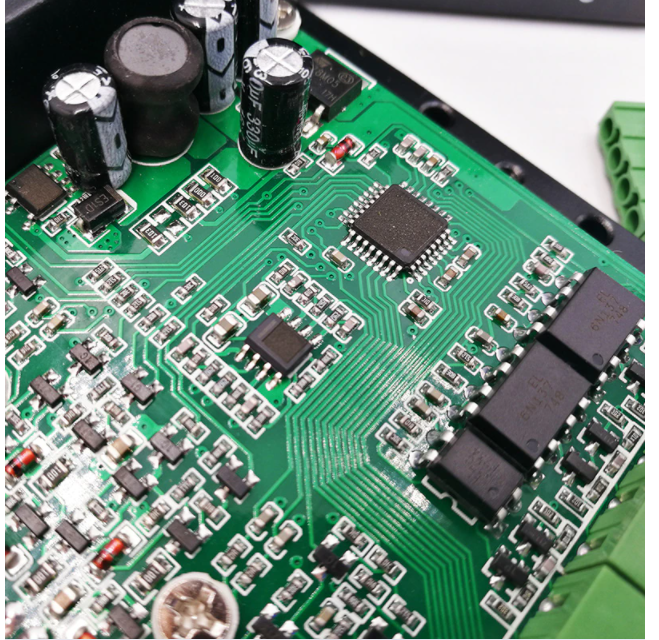

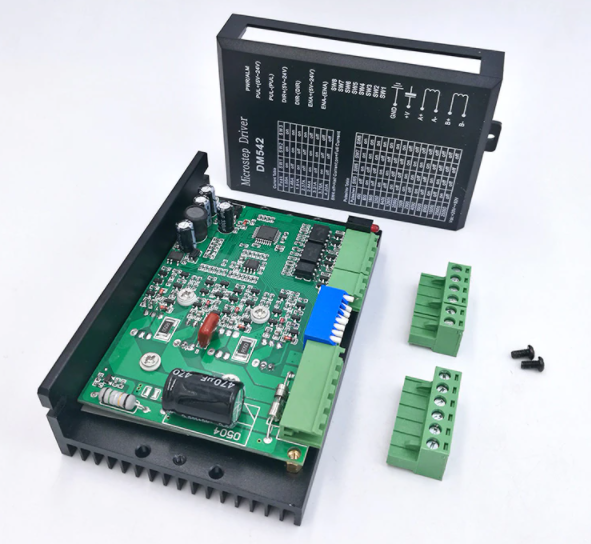

DM542 โมดูลขับสเต็ปปิ้งมอเตอร์ 20-50V 4.2A DSP digital 42/57/86 stepper motor driver engraving machine dedicated replacement 2M542/TB6600

| รหัสสินค้า | SKU-01785 |

| หมวดหมู่ | โมดูลขับมอเตอร์ (Motor Driver)/ อุปกรณ์ IO |

| ราคา | 450.00 บาท |

| สถานะสินค้า | พร้อมส่ง |

| ลงสินค้า | 2 พ.ย. 2564 |

| อัพเดทล่าสุด | 19 มี.ค. 2567 |

| จำนวน | ชิ้น |

- จำนวนและราคาสินค้าที่มีอยู่จริงจะตรงกับในเว็บ

- ถ้ากดใส่ตระกร้าได้แสดงว่ามีสินค้าพร้อมส่ง หากจำนวนไม่พอจะมีข้อความแจ้งจำนวนคงเหลือให้ทราบ

- การรับ/ส่งสินค้ามี 3 รูปแบบคือ ส่งพัสดุ / มารับเองที่ร้าน / บริการแอปขนส่งเช่น Grab, LALAMOVE, ฺBolt, อื่นๆ

รายละเอียดสินค้า

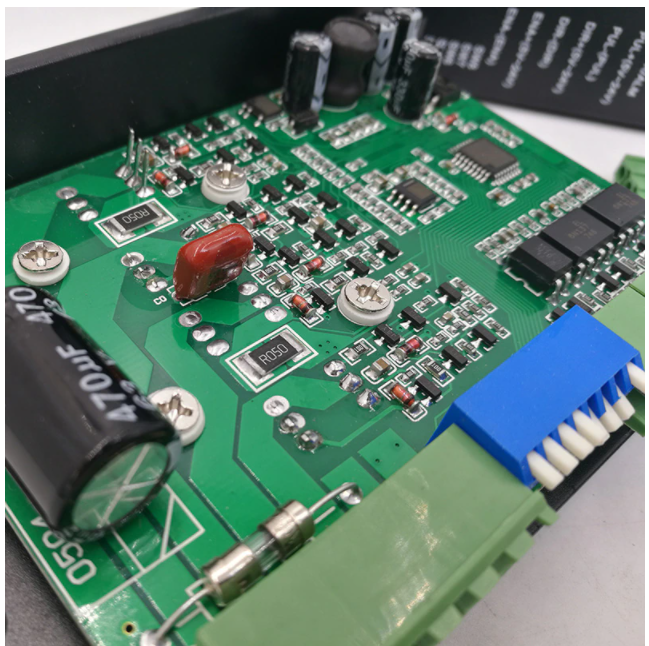

1. Electrical parameters:

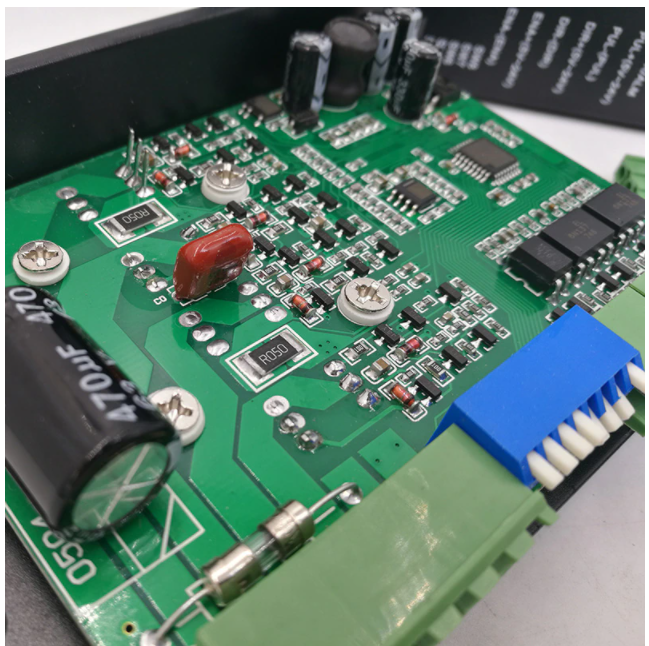

1.Driver Integrated Overvoltage and overcurrent Protection

2.Input signal isolate

3.Bipolar constant chopping method

4.Power supply DC 20~50VDC (24~48VDC recommended)

5.Maximum drive current 4.2A

6.Output dial switch adjust

7.Low Speed ZERO Vibration with minimal noise

8.High anti-interference ability and reliability.

9.Power Consumption: Power Consumption: 80W; Within insurance: 6A

10.Temperature: temperature -10 ~ 45 ℃; Temperature -40℃~70℃

11.Humidity: non-condensing, condensation

12.Gas: Flammable Gas and Conductive Dust

13.Weight: 200g

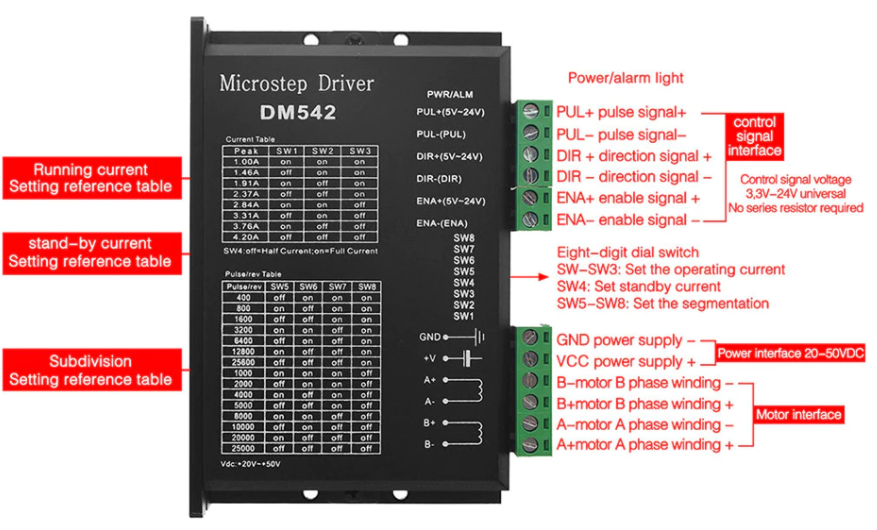

2.Control signal interface:

1. High definition control signal

PLS+: step pulse signal positive terminal or step positive pulse signal input positive terminal

PLS-: step pulse signal input negative terminal or step positive pulse signal input negative terminal

DIR+: Step direction signal positive terminal or reverse step pulse signal positive terminal

DIR-: step direction signal input negative terminal or reverse step pulse signal input negative terminal

ENA+: Offline enable signal reset input positive terminal

ENA-: Offline enable negative terminal input reset signal.

When the offline enable signal is valid, the drive fault is reset, any valid pulse is prohibited, the output power of the drive element is turned off, and the motor has no holding torque.

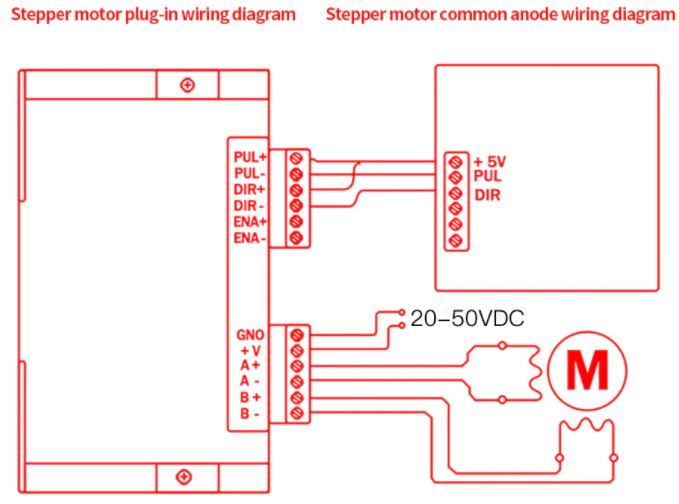

2.Control signal connection

The host computer control signal can have a high level performance or a low level. When effective high, connect the negative ends of all control signals together as the signal GROUND, when LOW, connect the positive ends of all control signals together as the common signal end. The circuit diagram interface is as follows:

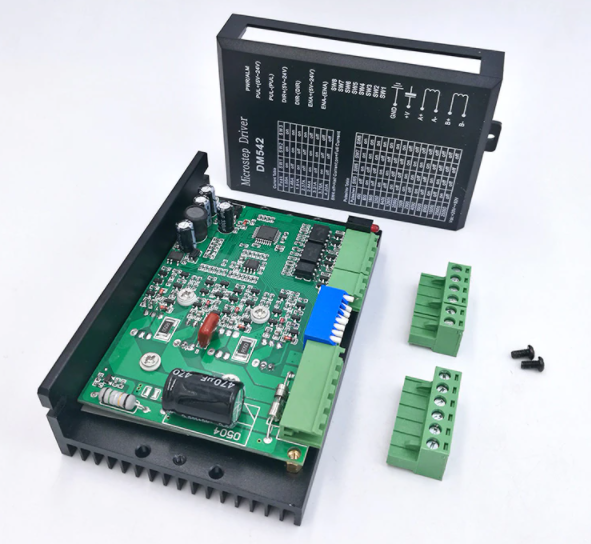

Wire drive:

A complete stepper motor control system should include stepper drives, DC power supplies and controllers (pulse sources).

The following is a general system wiring diagram:

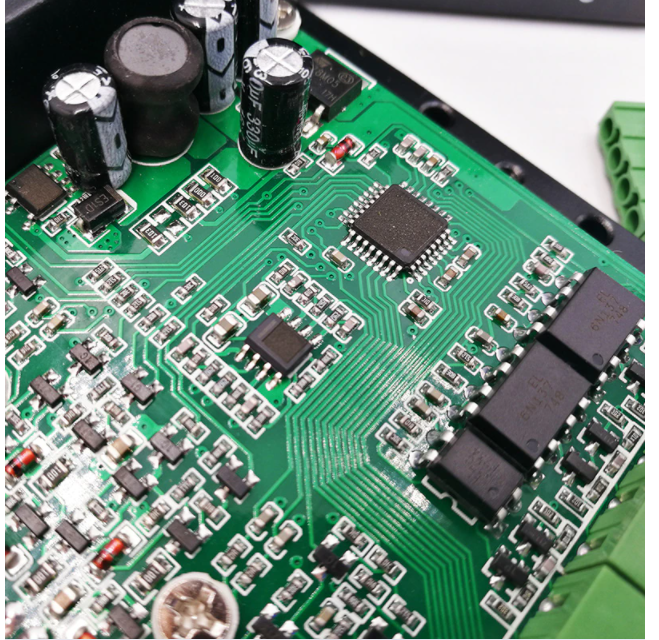

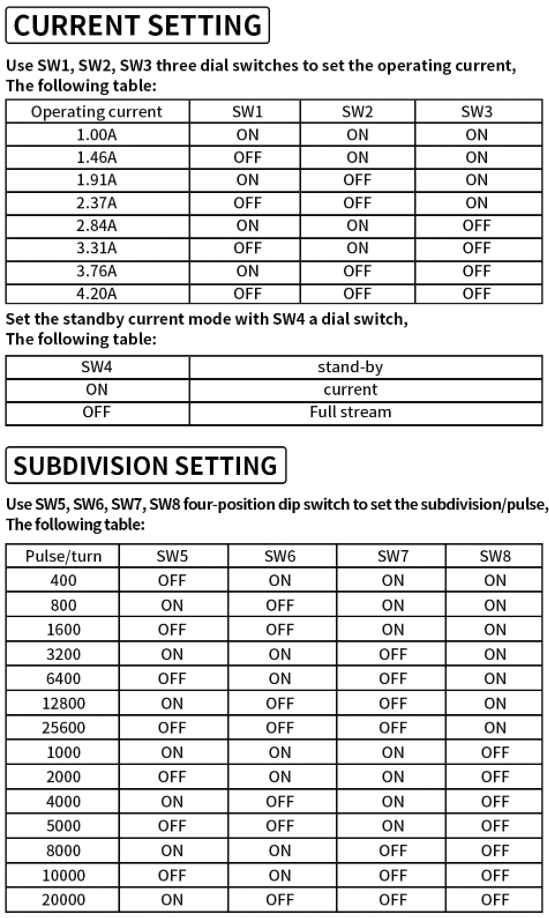

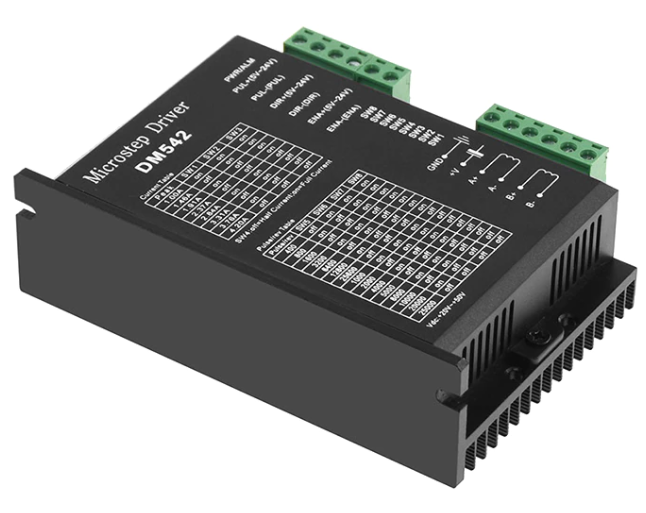

3. Set the current phase

In order to drive stepper motors with different torques, users can set the phase current. (effective value) of the drive amp through the DIP switches SW1, SW2, and SW3 on the drive panel, the corresponding output current of each switch position, and the pattern can be different. The corresponding output current value is different. See the table for details.

4. Interface:

1.V, GND: Connect the Driver Power Supply.

+V: DC positive, voltage DC 16~50V High current is 4.2A.

GND: Negative DC level

2. A + AB + B-: Connect the 2-Phase HYBRID Stepping Motor.

The connection between the driver and the 2-phase hybrid stepping motor uses four wires. The motor winding has a parallel and connection method, and the parallel connection method has good speed performance, but the driver current is large (1.73 times the motor winding current).

In series connection driver current is equal to motor winding current.

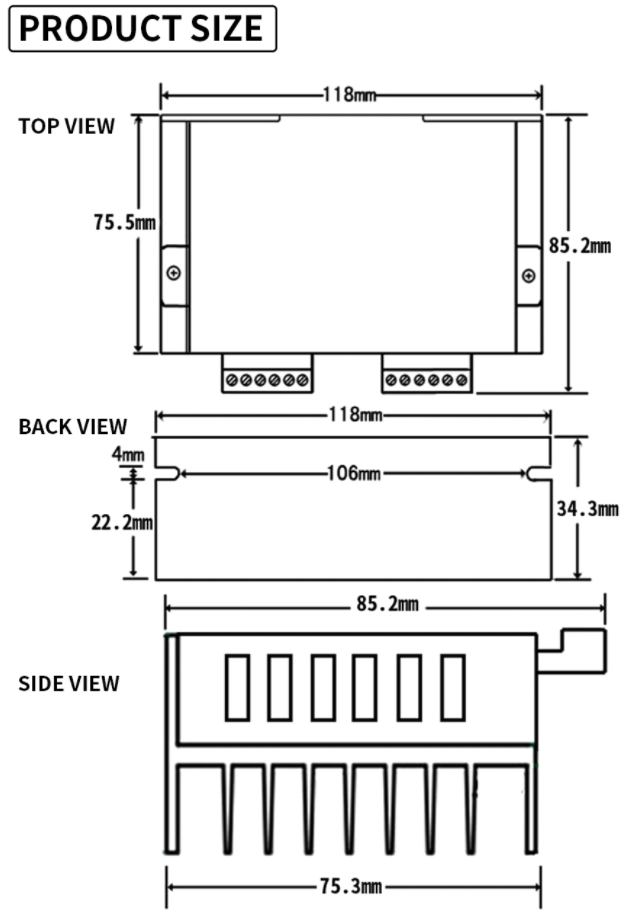

5. Installation:

There should be a space of 20mm around and should not be placed next to other heating equipment. Avoid Dust, Oil Mist, Excessive Corrosive Gas, Humidity and Strong Vibration.

Troubleshooting:

1. Status indicator light

RUN: Green, ON during normal use.

ERR: Red light, when a fault occurs, the circuit between the motor steps, G voltage and under voltage protection.

2. Failure and Troubleshooting

Solution: 1 check the power cord 2 increase the power supply voltage

Solution: Incorrect reset/correct motor connection.

Solution: Adjust the pulse and signal level.

Solution: Interchange two wires to connect and change direction setting.

วิธีการชำระเงิน

ชำระเงินผ่านธนาคาร

ชำระเงินด้วยการ Scan QR

นโยบายการเปลี่ยนหรือคืนสินค้า

หมายเหตุ

ต้องไม่เสียหายอันเกิดจากใช้งานผิดพลาด ใช้ผิดวิธี ต่อไฟผิดขั้ว จ่ายไฟเกินกำหนด หรืออื่นๆที่ตรวจสอบแล้วไม่ได้เกิดจากความผิดพลาดจากการผลิตสินค้า

ค้นหาสินค้า/Search

ค้นหาเลขพัสดุ/Track

Categories

Statistic

| หน้าที่เข้าชม | 564,481 ครั้ง |

| ผู้ชมทั้งหมด | 322,124 ครั้ง |

| ร้านค้าอัพเดท | 23 ต.ค. 2568 |

Member

- ระดับ{{userdata.dropship_level_name}}

- ไปหน้าหลักตัวแทน

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน {{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- รอยืนยันได้รับสินค้า {{(order_nums && (order_nums.wait_receive || order_nums.wait_confirm))?'('+(order_nums.wait_receive+order_nums.wait_confirm)+')':''}}

- รอตรวจสอบข้อร้องเรียน {{(order_nums && order_nums.dispute)?'('+order_nums.dispute+')':''}}

- เรียบร้อยแล้ว {{(order_nums && order_nums.completed)?'('+order_nums.completed+')':''}}

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน{{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- ส่งสินค้าเรียบร้อยแล้ว {{(order_nums && order_nums.sent)?'('+order_nums.sent+')':''}}

อีเมล : mikroelec@gmail.com

TOP เลื่อนขึ้นบนสุด